Modelo :

DW-325Tipo :

Plunger PumpAtaque :

4.5 Inches / 114.3 mmDiámetro del cilindro :

35-114mmFluir :

56.8-2346.7LPM/15-620GPMPresión :

6-58MPaPuerto de embarque :

Shanghai Port, ChinaGarantía :

12 MonthsPresupuesto:

| Estándar de diseño | API-674, Tercera edición |

| Configuración | Émbolo quíntuple horizontal |

| Número de émbolos | 5 |

| Servicio continuo | 265 CV |

| Servicio intermitente | 325 CV |

| Longitud de carrera | 4,5 pulgadas / 114,3 mm |

| Capacidad de carga del marco | 12.500 libras / 5670 kg |

| Peso de la bomba (promedio) | 4500 libras / 2041,2 kg |

| Clasificación de velocidad de servicio intermitente | 400 RPM |

| Clasificación de velocidad de servicio continuo | 330 RPM |

| Velocidad mínima | 100 RPM |

| Eficiencia mecánica | 90% |

| Sistema de lubricación | Salpicadura, Retorno de gravedad |

| Capacidad de aceite del cárter | 16 galones / 60,56 L |

| Tipo de aceite lubricante | SAE30 |

| Rango de temperatura del fluido | -20~350°F/-28~176°C |

| Tipo de válvula | Válvula de disco / Válvula resistente al desgaste |

Datos de rendimiento (métrica):

| Modelo de bomba | Émbolo Diámetro (mm) | Desplazamiento (L/REV) | Máximo Presión (MPa) | Caudal de la bomba (LPM) a velocidad de entrada (RPM) | |||||

| 100 | 200 | 300 | 350 | 400 | 425 | ||||

| DW32511 | 35 | 0.5473 | 58 | 56.8 | 109.8 | 166,5 | 181,7 | 193.0 | 219,5 |

| DW32512 | 38 | 0.6514 | 49 | 64.3 | 128,7 | 196,8 | 215.7 | 227.1 | 261.2 |

| DW32514 | 44 | 0.8868 | 36 | 87.1 | 177.9 | 265.0 | 291.4 | 310.4 | 355.8 |

| DW32516 | 51 | 1.1582 | 28 | 117.3 | 230.9 | 348.2 | 382.3 | 405.0 | 461,8 |

| DW32518 | 57 | 1.4659 | 21 | 147,6 | 295.2 | 439.1 | 484,5 | 514.8 | 586,7 |

| DW32520 | 64 | 1.8096 | 17 | 181,7 | 363.4 | 541.3 | 598.0 | 632.1 | 722.9 |

| DW32522 | 70 | 2.1896 | 14 | 219,5 | 439.1 | 658.6 | 722.9 | 764,6 | 874.3 |

| DW32524 | 76 | 2.6060 | 12 | 261.2 | 522.3 | 783,5 | 859.2 | 912.2 | 1040.9 |

| DW32526 | 83 | 3.0583 | 10 | 306.6 | 613.2 | 916.0 | 1010.6 | 1071.2 | 1222.6 |

| DW32528 | 89 | 3.5469 | 9 | 355.8 | 707.8 | 1063,6 | 1169,6 | 1241.5 | 1419.4 |

| DW32530 | 95 | 4.0719 | 8 | 408.8 | 813.8 | 1222.6 | 1343,7 | 1426.9 | 1627.6 |

| DW32532 | 102 | 4.6328 | 7 | 461,8 | 927.3 | 1389.1 | 1529.1 | 1620.0 | 1854.7 |

| DW32534 | 108 | 5.2301 | 6 | 522.3 | 1044.7 | 1570.8 | 1726.0 | 1831.9 | 2093.1 |

| DW32536 | 114 | 5.8633 | 6 | 586,7 | 1173.4 | 1760.0 | 1934.1 | 2051.5 | 2346.7 |

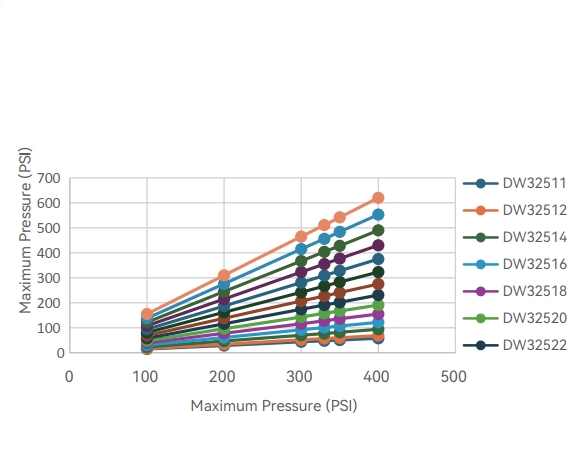

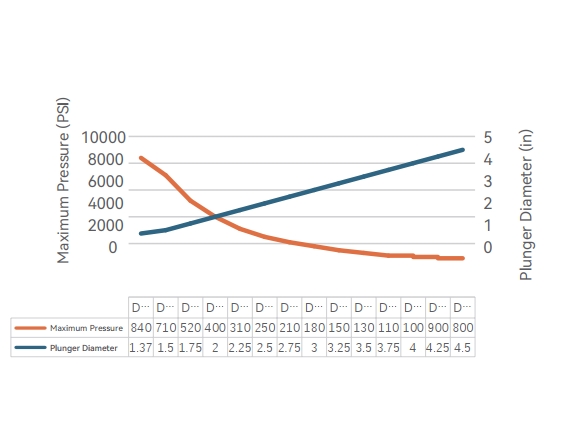

Actuación Datos:

| Bomba Modelo | Émbolo Diámetro (en) | Desplazamiento (GAL/REV) | Máximo Presión (PSI) | Capacidad de la bomba (GPM) a velocidad de entrada (RPM) | |||||

| 100 | 200 | 300 | 350 | 400 | 425 | ||||

| DW32511 | 1.375 | 0.1446 | 8400 | 15 | 29 | 44 | 48 | 51 | 58 |

| DW32512 | 1.5 | 0.1721 | 7100 | 17 | 34 | 52 | 57 | 60 | 69 |

| DW32514 | 1.75 | 0.2343 | 5200 | 23 | 47 | 70 | 77 | 82 | 94 |

| DW32516 | 2 | 0.306 | 4000 | 31 | 61 | 92 | 101 | 107 | 122 |

| DW32518 | 2.25 | 0.3873 | 3100 | 39 | 78 | 116 | 128 | 136 | 155 |

| DW32520 | 2.5 | 0.4781 | 2500 | 48 | 96 | 143 | 158 | 167 | 191 |

| DW32522 | 2,75 | 0.5785 | 2100 | 58 | 116 | 174 | 191 | 202 | 231 |

| DW32524 | 3 | 0.6885 | 1800 | 69 | 138 | 207 | 227 | 241 | 275 |

| DW32526 | 3.25 | 0.808 | 1500 | 81 | 162 | 242 | 267 | 283 | 323 |

| DW32528 | 3.5 | 0.9371 | 1300 | 94 | 187 | 281 | 309 | 328 | 375 |

| DW32530 | 3,75 | 1.0758 | 1100 | 108 | 215 | 323 | 355 | 377 | 430 |

| DW32532 | 4 | 1.224 | 1000 | 122 | 245 | 367 | 404 | 428 | 490 |

| DW32534 | 4.25 | 1.3818 | 900 | 138 | 276 | 415 | 456 | 484 | 553 |

| DW32536 | 4.5 | 1.5491 | 800 | 155 | 310 | 465 | 511 | 542 | 620 |

Tamaños de conexión estándar:

| Modelo de bomba | Succión (entrada) | Descarga (en) |

| DW32511-DW32518 | 4.0 | 2.0 |

| DW32520-DW32528 | 6.0 | 3.0 |

| DW32530-DW32536 | 8.0 | 4.0 |

Materiales de los cilindros de fluidos:

| Materiales para cilindros de fluidos | Elenco |

| Acero carbono | Hierro dúctil |

| Acero al carbono de alta resistencia | Bronce de aluminio |

| Acero inoxidable 304 / 316L / 17-4PH / 2205 / 2507 |

*Los materiales especiales están disponibles bajo petición.

esquema dimensional de ingeniería

Ventajas

Las ventajas de bombas de inyección química Su alta eficiencia y fiabilidad son sus principales ventajas. En primer lugar, estas bombas mantienen un rendimiento estable incluso en condiciones operativas complejas, destacando en tareas que pueden ocurrir a altas temperaturas, presiones elevadas o en entornos altamente corrosivos. En segundo lugar, su diseño prioriza la comodidad operativa. Gracias a la integración de estructuras modulares y sistemas de control inteligentes, los usuarios pueden ajustar fácilmente los parámetros y supervisar el estado, lo que mejora significativamente la eficiencia del trabajo. Además, el cuerpo de la bomba emplea técnicas de fabricación avanzadas, lo que garantiza su durabilidad durante un funcionamiento prolongado y reduce la necesidad de un mantenimiento frecuente. Sus características de ahorro energético también son destacables; gracias a un diseño hidrodinámico optimizado, el consumo de energía se minimiza, lo que supone un importante ahorro en los costes operativos para los usuarios. Estas ventajas combinadas convierten a las bombas de inyección química en el equipo preferido en numerosos sectores industriales, proporcionando un sólido soporte técnico para la producción química moderna.

Perfil de la empresa

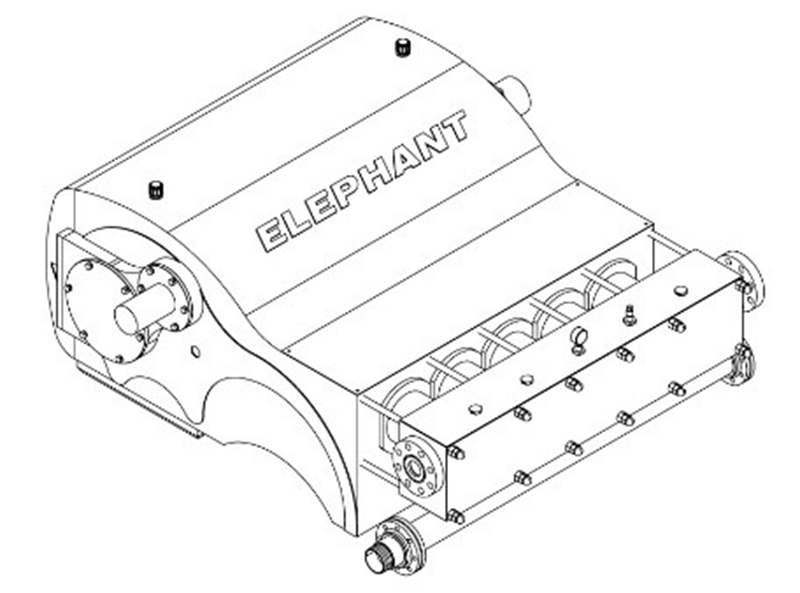

Elephant Machinery se especializa en la I+D y la fabricación de bombas reciprocantesLa empresa ofrece a sus clientes soluciones de transferencia de fluidos de alta calidad. Equipada con instalaciones de producción de vanguardia y un equipo profesional, ofrece productos personalizados para garantizar un rendimiento óptimo de las bombas en aplicaciones reales. Su línea de productos abarca diversas bombas de inyección ampliamente utilizadas en industrias como la petrolera y gasífera, la química y otras.

Como líder del sector, Elephant Machinery prioriza la innovación tecnológica y la mejora continua de la calidad. Sus productos se someten a rigurosas pruebas antes de su envío, lo que garantiza un rendimiento estable y fiable. La empresa también ofrece un completo soporte técnico y servicio posventa, resolviendo eficazmente cualquier problema con los equipos para ganarse la confianza de sus clientes.

Además, Elephant Machinery monitorea las tendencias del sector e introduce innovaciones continuamente. Mediante colaboraciones con instituciones de investigación, avanza en ciencia de materiales, tecnología de sellado y sistemas de control inteligentes, mejorando la competitividad de sus productos y generando mayor valor para sus clientes. De cara al futuro, Elephant Machinery mantendrá su compromiso con la excelencia, ofreciendo soluciones superiores de bombas reciprocantes a usuarios de todo el mundo.